A WPC decking board test according to EN standard 15534 reveals: TITANWOOD WPC is better! In this article we show you the differences in quality of WPC decking boards. This can help you decide on a WPC decking board. After all, WPC boards differ enormously and this cannot be seen at first glance.

Content

- 1 WPC decking board test shows: TITANWOOD is more durable

- 2 WPC decking board bending strength test: TITANWOOD withstands more

- 3 WPC decking board impact resistance test: TITANWOOD does not break as quickly

- 4 TITANWOOD WPC boards are easier to care for

- 5 TITANWOOD WPC boards withstand temperature fluctuations better

- 6 TITANWOOD WPC boards withstand moisture fluctuations better

- 7 WPC decking boards test - a table overview

- 8 Quality comparison of WPC decking boards

- 9 TITANWOOD WPC boards are guaranteed to last 20 years

There is the European standard EN 15534 for composite materials such as WPC decking boards. Here, WPC boards are put through their paces according to defined test criteria. This standard sets the same quality standards for WPC decking boards throughout Europe. This is good. It allows you to compare WPC decking boards on the same basis. The standard is one thing, the practical difference in WPC boards is another.

German and European weather conditions in particular are highly variable. They put an enormous strain on WPC decking. That is why it is important to know the practical properties of WPC boards. From this you can draw conclusions for the benefit of your WPC decking boards

"The Titanwood WPC decking board test shows outstanding results in all important disciplines!"

What is special about TITANWOOD WPC boards? What are the impressive properties of TITANWOOD WPC boards? What benefits do you get from TITANWOOD WPC decking boards?

In this test, we will give you 7 reasons why you’ll benefit from using TITANWOOD WPC decking boards.

WPC decking board test shows: TITANWOOD is more durable

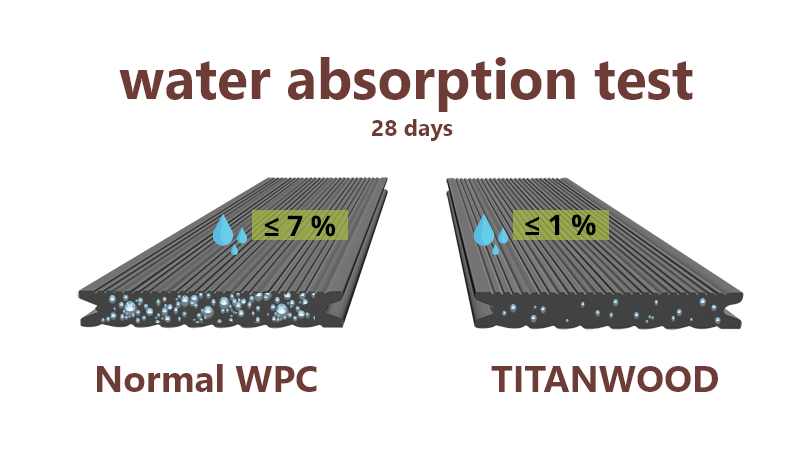

The longevity of a WPC board is crucially related to the water absorption of the WPC material. Hollow chamber profiles in particular offer twice as much surface area for moisture as solid planks. The inner chambers of the WPC boards have approximately as much surface area as the entire board.

In addition, boards with a large proportion of wood have a comparatively higher water absorption rate. The more water a WPC board can absorb, the faster it decomposes. The material literally rots. This can even be faster than with solid wood if the WPC boards can absorb a lot of water.

A WPC decking board test determines the water absorption after a fixed 28-day cycle. The test planks are exposed to boiling water and frost alternately.

The TITANWOOD WPC decking board test in the water absorption category is below 1%, while the EN standard allows a maximum of 8%.

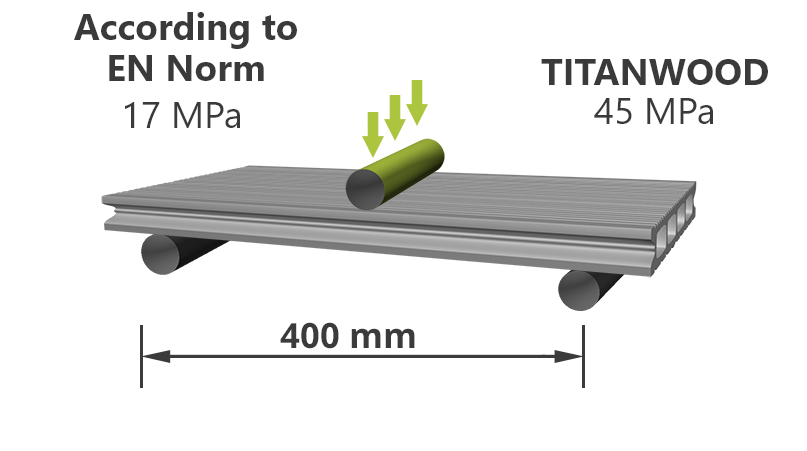

WPC decking board bending strength test: TITANWOOD withstands more

How much weight can a WPC board withstand? This question determines the load-bearing capacity of an entire terrace. WPC boards must offer enough safety for use at the weakest point.

This can be tested by loading the boards between two defined support points until they burst. The value is then defined as the bending strength.

The TITANWOOD WPC decking board test shows a load value higher than 45 MPa (Megapascal), while the Euro standard is already satisfied at 17 MPa. This corresponds to a load of 450 kg/cm² pressure on the board. Only then does it give way at the weakest point and break

This makes TITANWOOD WPC decking boards 2.5 times more resistant than normal WPC decking boards. This gives you a particularly high level of safety in use, even if your barbecue turns out to be more extensive than planned.

WPC decking board impact resistance test: TITANWOOD does not break as quickly

What can a WPC decking board withstand if something heavy is dropped on it? The impact resistance is determined with the so-called ball drop test. In this test, a test piece weighing 1 kg falls from a height of 70 cm with a spherical surface. In the EU, the test is considered passed if 1 kg of weight does not cause a crack longer than 10 mm in the surface of a hollow chamber board.

WPC decking boards can be subjected to a point impact load. A heavy object such as a parasol falls over. The wind blows a flower pot off the table or you serve a pot full of food for your friends and trip over shoes that have been left lying on the floor.

TITANWOOD passes this WPC decking board impact resistance test with flying colours. In addition, we have carried out our own practical tests. Because standard tests only depict a special artificial situation.

TITANWOOD WPC boards are easier to care for

WPC boards become dirty over time. Fine dirt particles collect on the surface which can eventually develop into a green coating. The more water WPC boards absorb, the slower they dry again. This is a good basis for moss and fungi, which can also penetrate the surface.

The standards according to EN 15534 require a water absorption for WPC boards not higher than 8% within 28 days. The standard thus sets standards especially for our relatively wet seasons from autumn to spring.

TITANWOOD achieves a water absorption rate of less than < 1%. This extremely low value ensures that the boards dry faster. Moss, green cover and deep soiling are therefore much less likely to occur. This makes the maintenance of the WPC terrace much easier. Superficial soiling can be cleaned more easily with water.

TITANWOOD WPC boards withstand temperature fluctuations better

A WPC decking board test of EN 15534 deals with the expansion in length with temperature changes. In Europe, WPC boards are exposed to strong temperature fluctuations throughout the year. While winter temperatures can reach -30°C in some regions, we have air temperatures of 30°C and more in summer. The direct radiation of the sun then triggers surface temperatures well above this.

TITANWOOD WPC boards have a more dimensionally stable material composition than other WPC boards. Dimensional changes due to temperature fluctuations are therefore less than with conventional WPC boards.

TITANWOOD WPC boards withstand moisture fluctuations better

Long rainy seasons over autumn and winter are often followed by extended periods of dry weather. What does changeable weather do to WPC decking boards?

As water absorption in WPC boards increases, the material strength decreases. WPC boards therefore have a reduced bending strength when exposed to moisture. Water therefore leads to a reduction in the stability of WPC boards.

EN 15534 requires a maximum reduction in the bending strength of WPC boards of 20% after an extreme cyclical climate test. However, this only says something about the strength in the 28-day climate test. If the strength can be reduced by up to 20% within this short period, what does this mean for the service life of these WPC boards?

In the WPC decking board test, TITANWOOD achieved the top value with less than 5% reduction in bending strength. In practical terms, we can deduce that TITANWOOD WPC boards cope much better with moisture and the typical changeable weather conditions. The strength of the material therefore only decreases to a very small extent.

This means that the TITANWOOD WPC boards can achieve a much longer service life..

planeo TitanWood - solid plank dark brown antique aged/brushed

0,00 € pro rm

planeo TitanWood - solid plank dark brown antique aged/brushed

0,00 € pro rm

planeo TitanWood - solid plank wood structure dark brown 5m sawed/textured

10,50 € pro rm

planeo TitanWood - solid plank wood structure dark brown 5m sawed/textured

10,50 € pro rm

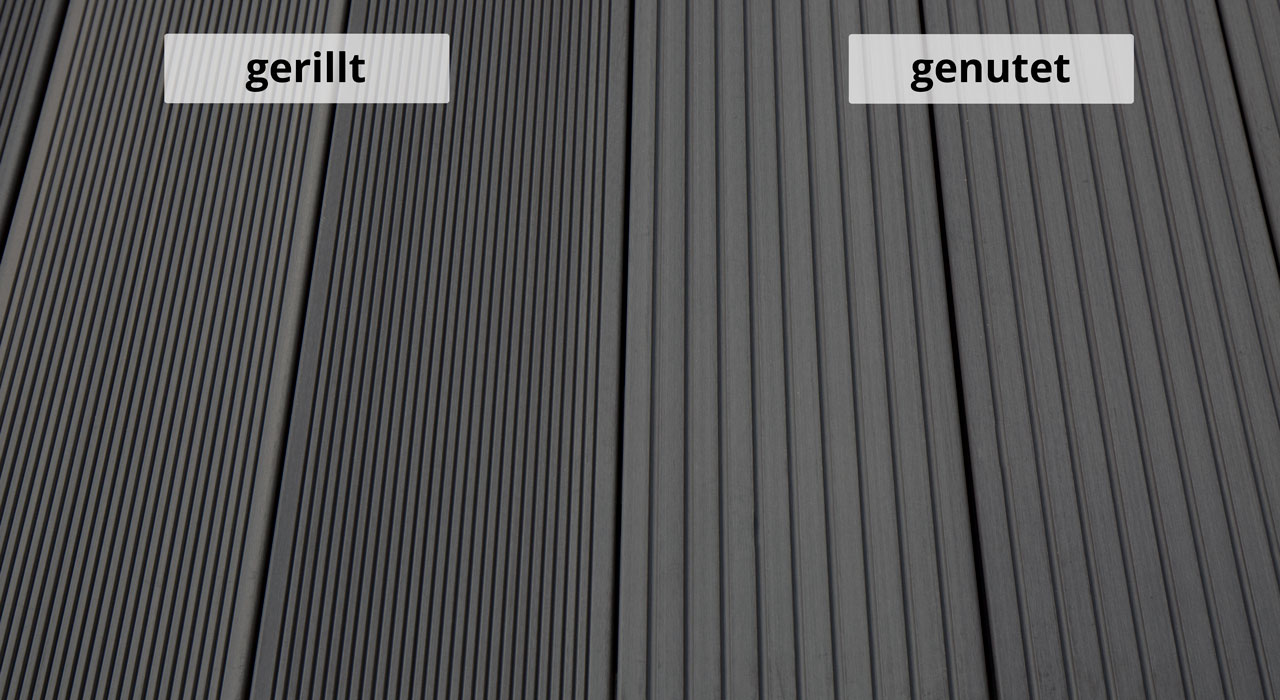

planeo TitanWood - solid plank 3m dark grey grooved/grooved

13,85 € pro rm

planeo TitanWood - solid plank 3m dark grey grooved/grooved

13,85 € pro rm

planeo TitanWood - solid plank wood structure light grey 4m sawed/textured

14,45 € pro rm

planeo TitanWood - solid plank wood structure light grey 4m sawed/textured

14,45 € pro rm

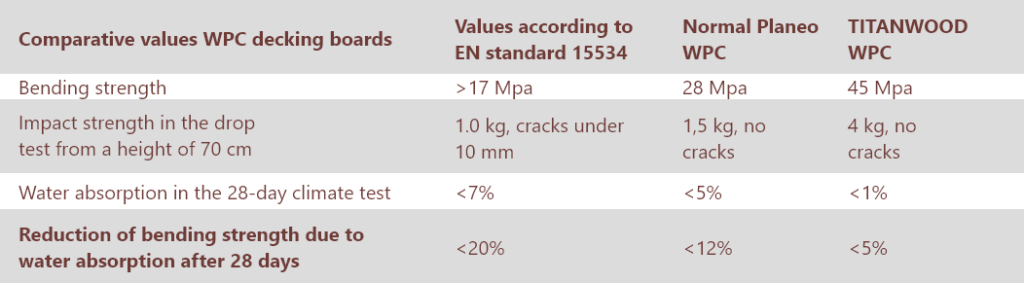

WPC decking boards test - a table overview

Here you will find the important comparative values of the WPC decking boards in a tabular overview:

Quality comparison of WPC decking boards

This table compares important test results based on the valid EN standard 15534

TITANWOOD WPC boards are guaranteed to last 20 years

Many patio owners have had experience with WPC. The experiences with WPC decking boards are very different. WPC decking "Made in Germany" - even if it is from market leaders - is unfortunately no guarantee for a long service life.

Many patio owners have had experience with WPC. The experiences with WPC decking boards are very different. WPC decking "Made in Germany" - even if it is from market leaders - is unfortunately no guarantee for a long service life.

No one wants to experience a second time that WPC boards burst, break through and disintegrate from the inside after only a few years. When asked about the lifespan, manufacturers are reluctant to give guarantees due to relevant experience.

Your TITANWOOD WPC boards will not rot within 20 years. Guaranteed.

And here you can get free WPC samples of TITANWOOD.